-

office@corrmagnet.com

office@corrmagnet.com

-

1-403-991-4036

1-403-991-4036

-

sales@interlaceindia.com

sales@interlaceindia.com

-

+91 44 4741 4600

+91 44 4741 4600

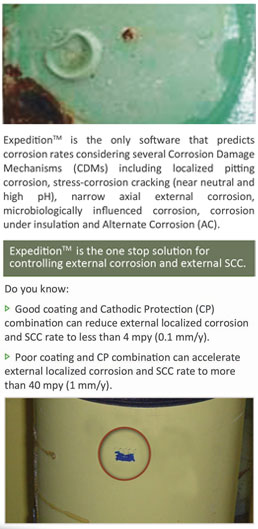

ExpeditionTM predicts external localized corrosion rate as well as external Stress-Corrosion Cracking (SCC) rates of carbon steel for oil and gas pipelines and facilities. Many leaks, ruptures and incidences are due to external localized pitting corrosion and SCC. ExpeditionTM helps oil and gas industry to minimize failures, ruptures and leaks due to external localized corrosion and SCC, and thereby leads to uninterrupted operation, cost savings, safe environments and enhanced corporate reputation.